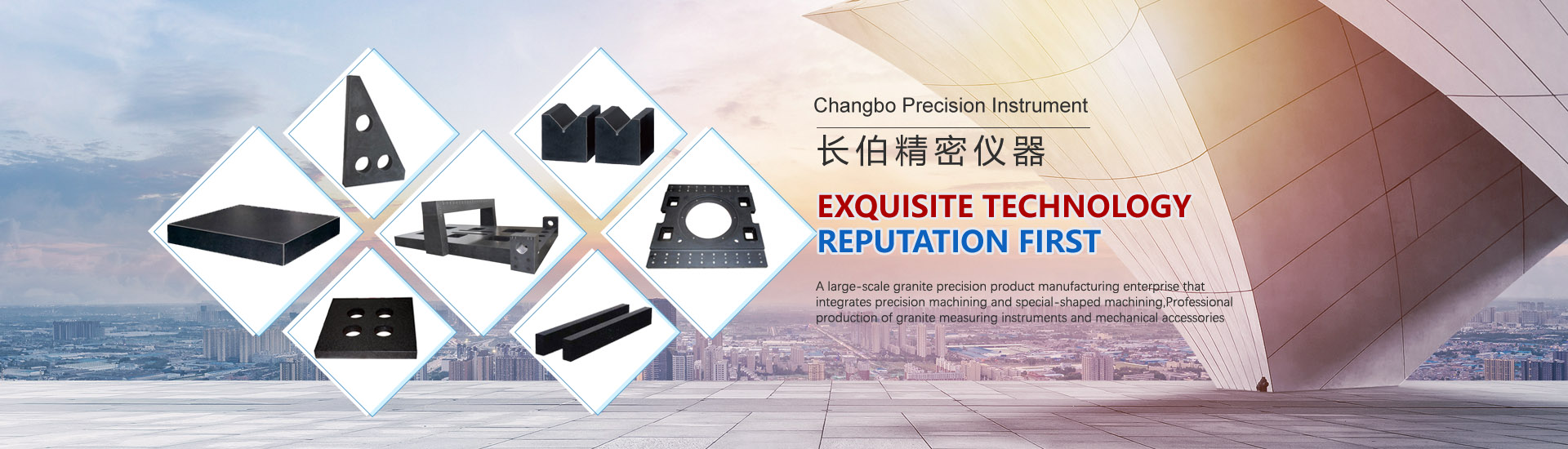

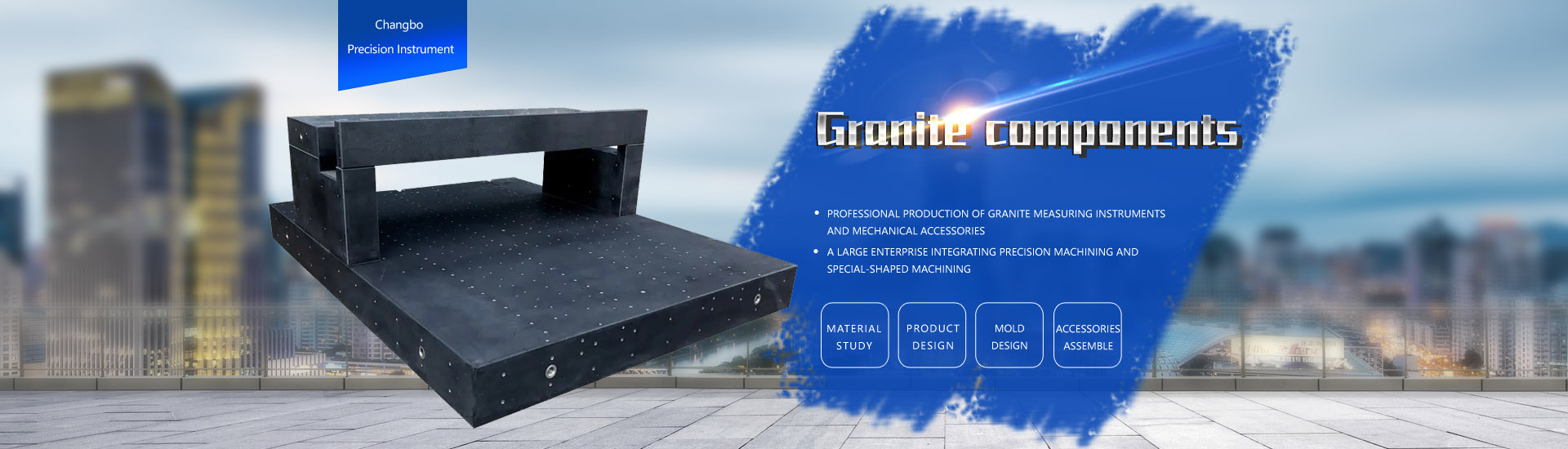

Mainly used to inspect the flatness of components. Granite measuring tools are basic instruments used in industrial inspection, suitable for inspecting instruments, precision tools, mechanical parts, and high-precision measurement.

Material: Mainly composed of granite minerals, including pyroxene, plagioclase, a small amount of olivine, biotite, and trace amounts of magnetite. It has a black color, precise structure, uniform texture, good stability, high strength, high hardness, and can maintain high precision under heavy loads after billions of years of aging. Suitable for industrial production and laboratory measurement work.

Features and advantages:

1. Granite ruler has a dense organizational structure, smooth and wear-resistant surface, and low roughness values;

2. Granite has undergone long-term natural aging, and its internal stress has completely disappeared. The material is stable and will not deform;

3. Acid, alkali, corrosion, and magnetic resistance;

4. Will not get damp or rust, easy to use and maintain;

5. Small coefficient of linear expansion, less affected by temperature;

Verification method:

1. Polish the large board

1) Measurement method for thickness limit tolerance: Use a vernier caliper with a reading of 0.1mm to measure the midpoint of 4 edges. Use the difference between the maximum and minimum thickness values on the same board to represent the thickness range. The contract stipulates that the thickness of the board is 20MM, and the allowable range is plus or minus 1MM.

(2) Measurement method for ultimate tolerance of flatness plate: Use a steel ruler with a reading of 0.1mm and a length of 1000mm to measure. Place the steel ruler on the two diagonal corners of the plate, and use a feeler gauge to measure the gap between the ruler surface and the plate surface. The contract stipulates that the ultimate tolerance of the TodayHot board plane is 0.80MM

3) Length and width measurement method: Use a steel ruler with a reading of 1MM to measure. Measure three straight lines for length and width respectively, and use the average value as the standard. Record the length and width of the board for later quantity calculation.

2. Floor slabs

1) Measurement method for thickness limit tolerance: Use a vernier caliper with a reading of 0.1mm to measure the midpoint of 4 edges. Use the difference between the maximum and minimum thickness values on the same board to represent the thickness range. The contract stipulates that the floor thickness is 10MM, and the allowable range is plus or minus 0.50mm.

2) Measurement method for flatness limit tolerance: Use a 0.1mm steel ruler to measure, place the steel ruler on the two diagonal corners of the plate, and use a feeler gauge to measure the gap between the ruler surface and the plate surface. The contract stipulates that the maximum tolerance of the floor plan is plus or minus 0.20MM

3) Length and width measurement method: Use a steel ruler with a reading of 1MM to measure. Measure three straight lines for length and width respectively, and use the average value as the standard. The maximum tolerance for the length and width of the floor specified in the contract is -1mm, and the floor is 305x305mm

4) Allowable limit tolerance for angle: Measure with a 90 degree steel ruler and feeler gauge with an internal angle perpendicularity tolerance of 0.13mm and an internal angle side length of 450x400mm. Place the two sides of the angle ruler tightly against the two edges of the board, and use a feeler gauge to measure the gap between the board and the edge of the angle ruler. Measure the four corners of the board using this method. The maximum allowable tolerance for the angle specified in the contract is 0.40MM