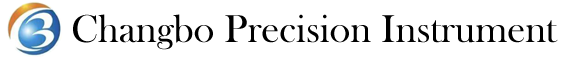

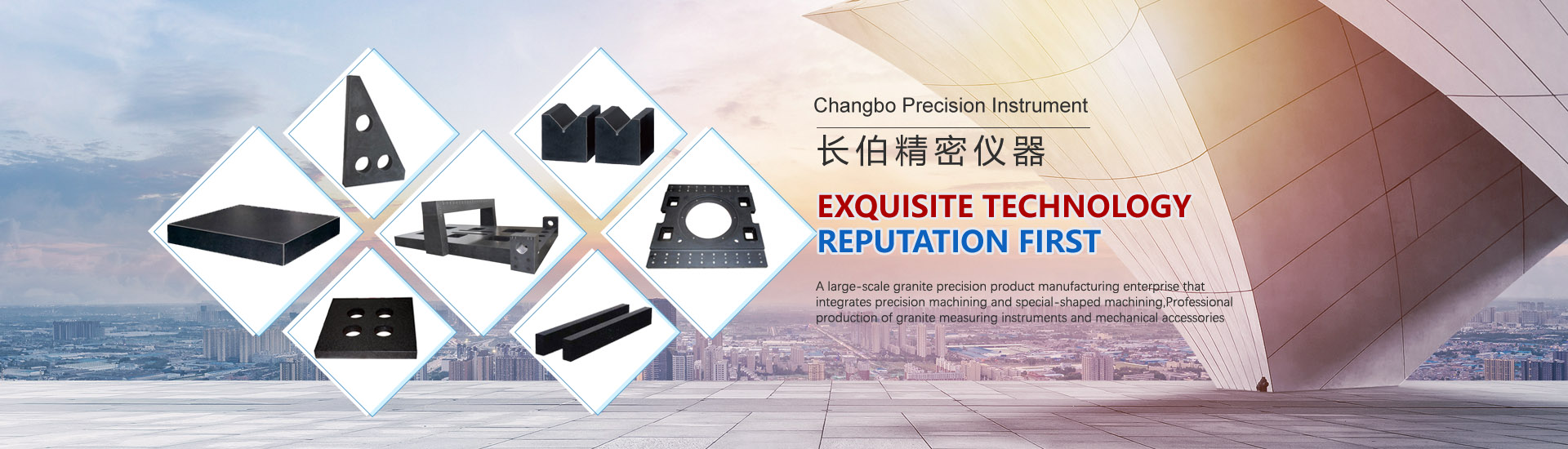

Marble components: can be processed with T-shaped grooves, punched holes, V-shaped grooves, dovetail grooves, and metal sleeves embedded in grooves or holes. Marble components are made of high-quality "Jinan green" stone material through mechanical processing and manual precision grinding. Black luster, precise structure, uniform texture, good stability, high strength, high hardness, able to maintain high precision under heavy load and general temperature, and has the advantages of non rusting, acid and alkali resistance, wear resistance, non magnetization, and invariance.

Characteristics of marble components:

1. Granite mechanical components have undergone long-term natural aging, with uniform organizational structure, extremely low coefficient of linear expansion, complete disappearance of internal stress, and no deformation.

2. Good rigidity, high hardness, strong wear resistance, and minimal temperature deformation.

3. Not afraid of acid and erosion, not rusting, no need to apply oil, not easy to stick to dust, easy to maintain and maintain, long service life.

4. No scratches will occur, not hindered by constant temperature conditions, and measurement accuracy can be maintained at room temperature.

5. Non magnetized, able to move smoothly during measurement, without any sluggishness, not affected by moisture, and with good flat stability.

Physical properties of granite mechanical components:

1. Specific gravity: 2970-3070kg/m3

2. Pressure resistance strength: 2500-2600kg/cm3

3. Elastic coefficient: 1.3-1.5 × 106kg/cm2

4. Water absorption rate:< 0.13%

5. Shore hardness: above HS70.