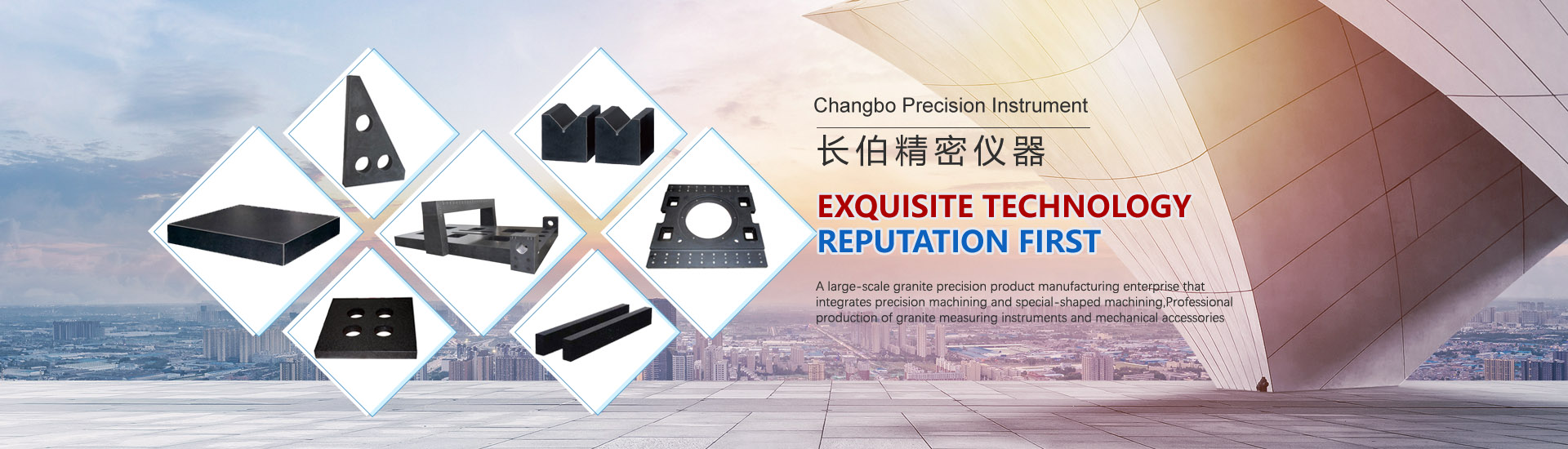

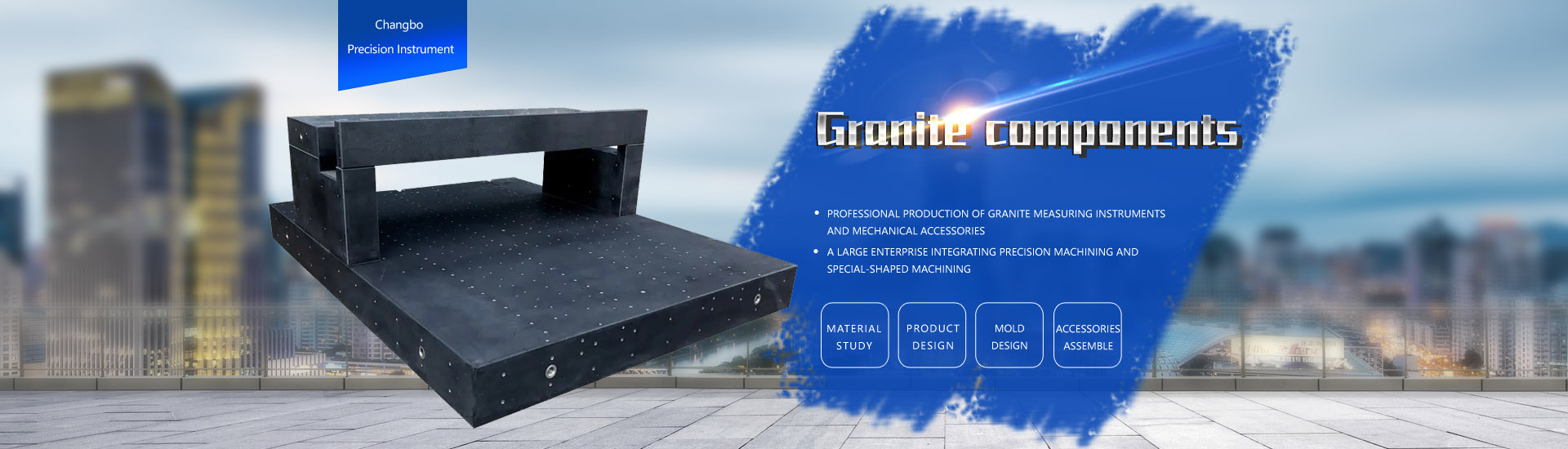

Granite slabs are precision reference measuring tools made of natural stone materials, which are ideal reference surfaces for the inspection of instruments, precision tools, and mechanical components. Especially for high-precision measurement, due to its unique characteristics, cast iron plates pale in comparison. Granite is made from high-quality rock layers underground, and after billions of years of natural aging, its shape is extremely stable, so there is no need to worry about deformation due to conventional temperature differences. After rigorous physical testing and selection, the granite material has fine crystals, a hard texture, a compressive strength of 2290-3750 kg/square centimeter, and a hardness of 6-7 Mohs hardness. Extremely wear-resistant, acid resistant, alkali resistant, with high corrosion resistance, and will never rust. Due to its non-metallic nature, granite has no magnetic reaction or plastic deformation. Its hardness is 2-3 times higher than cast iron (equivalent to HRC>51), so it has good accuracy retention. Even if rock tools are hit by heavy objects during use, they will only drop a few pieces of gravel at most, and will not damage accuracy due to deformation like metal tools. It is superior to precision measuring reference parts made of high-quality cast iron and steel, and can achieve high and stable accuracy.

advantage:

Natural granite is processed by machinery and finely ground by hand. Black luster, precise structure, uniform texture, and good stability. High strength and hardness. And it has the advantages of non rusting, acid and alkali resistance, non magnetization, invariance, and good wear resistance. Can maintain stability under heavy loads and normal temperatures.

Granite flat plate, precision granite flat plate, granite inspection flat plate, instrument platform, made of high-quality "Jinan green" stone material through mechanical processing and manual precision grinding. Black luster, precise structure, uniform texture, good stability, high strength, high hardness, able to maintain high precision under heavy load and general temperature, and has the advantages of non rusting, acid and alkali resistance, wear resistance, non magnetization, and invariance Granite slabs are suitable for measuring tools in mechanical factories.

characteristic:

The main characteristics of granite slabs are stable accuracy and easy maintenance. This is because:

① Granite slabs have a dense organizational structure, smooth and wear-resistant surface, and low roughness values;

② Granite has undergone long-term natural aging, and its internal stress has completely disappeared. The material is stable and will not deform;

③ Acid, alkali, corrosion, and magnetic resistance;

④ Will not get damp or rust, easy to use and maintain;

⑤ Small coefficient of linear expansion, less affected by temperature;

⑥ After collision or scratch on the working surface, only pits will be formed, without any protrusions or burrs, which has no impact on the measurement accuracy.

The main disadvantage of granite slabs is that they cannot withstand excessive impact and knocking, and will deform when exposed to high humidity, with a moisture absorption rate of 1%.