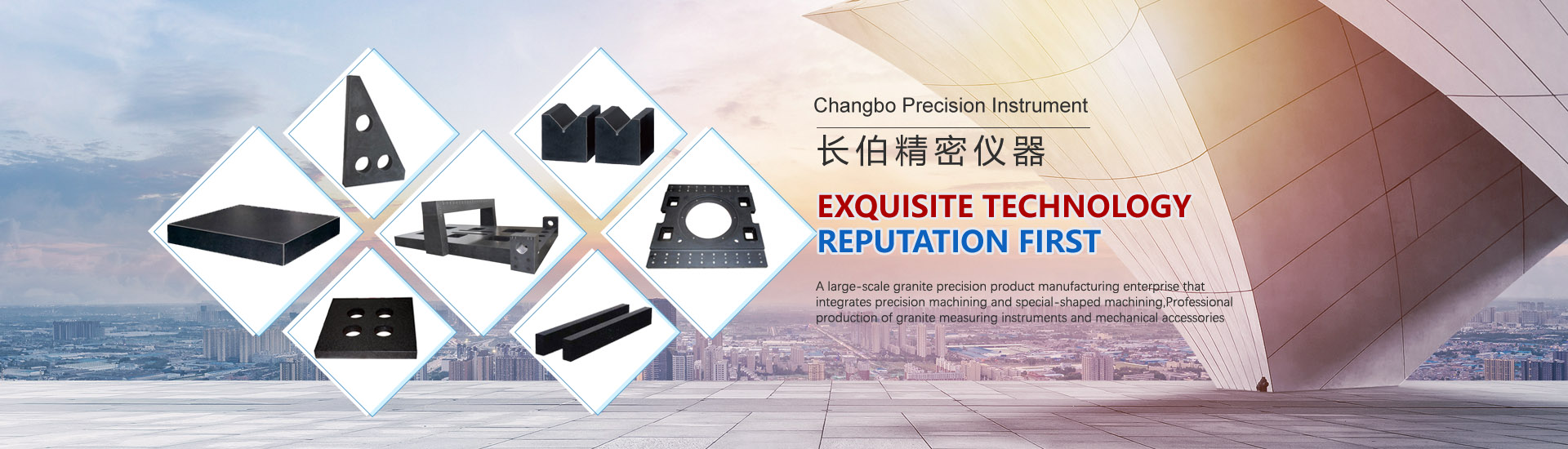

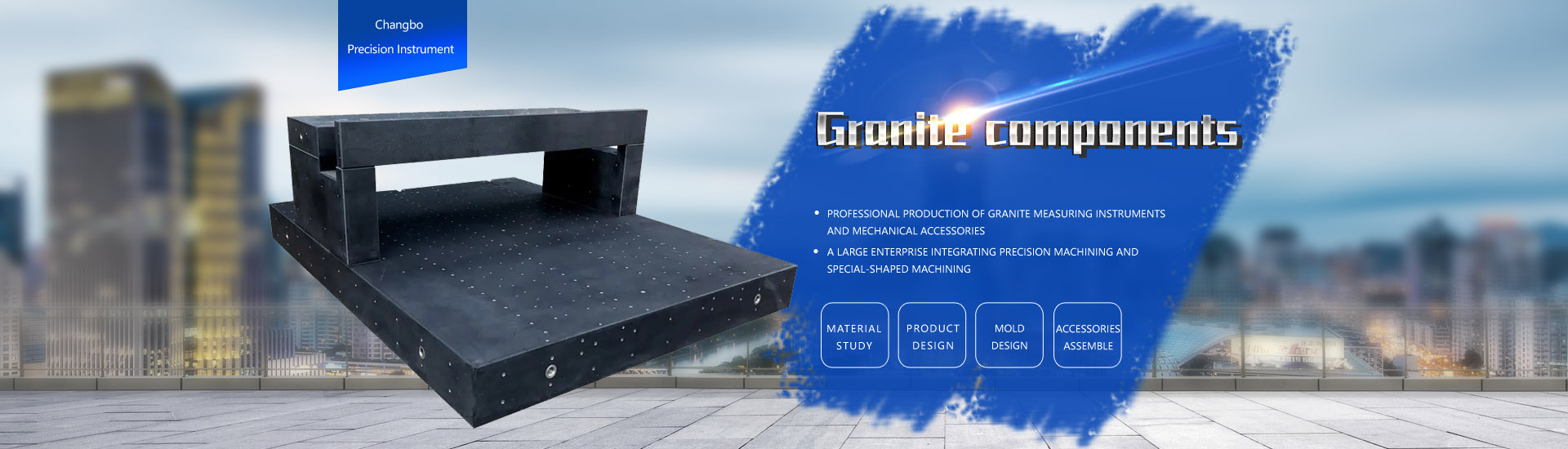

During the manufacturing process of granite mechanical components, the external dimensional error bi must be controlled within 1mm, and further deep processing must be carried out on the basis, with strict processing requirements. Let's follow the editor to learn about the tooling and measurement of granite mechanical components.

In the measurement of granite mechanical components, they can slide smoothly without any roughness. The measurement accuracy of the working face is precise, and general scratches do not affect the measurement accuracy. Granite components are made of stone and have the characteristics of non rusting, acid and alkali resistance, good wear resistance, and long service life, without the need for special maintenance. Granite mechanical components are commonly used as fixtures in the machinery industry, hence they are called granite mechanical components or granite components. The characteristics of granite mechanical components are basically the same as those of granite platforms.

Introduction to tooling and measurement of granite mechanical components:

Precision machining and microfabrication technology are important development directions in the mechanical manufacturing industry, and they have become important indicators for measuring a country's high-tech level. The development of various cutting-edge technologies and defense industries cannot be separated from precision machining and microfabrication technologies. Granite components can slide smoothly during measurement without any sense of stagnation. The measurement accuracy of the working face is precise, and general scratches do not affect the measurement accuracy. Granite components need to be designed and produced according to the requirements of the demand side.